Oxifree

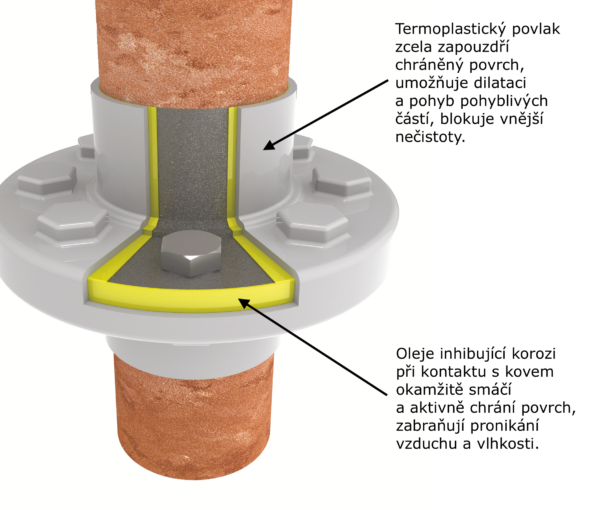

Thermoplastic coating TM198 is melted down from a solid resin and applied using a heated hose and gun. It provides an organic, pliable barrier coating, which will protect all types of metal components against galvanic pitting and atmospheric corrosion as well as protecting from water and dust ingress.

A key feature of the encapsulation system is the non-adherence to the substrate, along with the self lubricating properties, which allows any components that need to move to do so.

The material can easily be cut and removed for access and maintenance, the area of removed material can then be refilled as the newly applied material will bond to the existing coating. Alternatively the protected substrate can be inspected via ultrasonic testing directly through the material.

There is no downtime during application and protection is provided immediately, bringing savings to both CapEx and OpEx.

English

English